|

| |

Eric Metrot – Engineer -

Composite Materials / Sporting Goods

I started to use composite materials in 82 while studying mechanical

engineering (INSA Lyon France- GMD 86) to make my first wave sailboard and was

amazed straight away that it was about half the weight of the products available in

the shops.

Then

the snowboard came in and again, I made my own ones with which I competed successfully and

went on to produce in a series with the shop who was sponsoring me.

Since then, I have always been working in the composite world, in different

applications for the following companies:

|

|

Glen Oldfield – Technician

- Composite Materials

My composites experience began with home built construction of several

lightweight development class sailing dinghies, which inturn spurred an interest

in lightweight structural components.

After working

in the

composites

department at Eagle Aircraft, my interest grew and I gained further employment

with

internationally renowned companies on varying projects

from

land,

air

and

sea,

to

space.

|

|

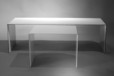

Composite Design,

Australia: a young

design team, formed in 2002 when Glen Oldfield and Penny Forlano, joined forces to explore the possibilities of carbon fibre and

composite construction for furniture production. They set out to combine

their joint skills to produce furniture utilising the most up to date

technology in composites, to create strong, lightweight and extremely thin

products, that are timeless yet contemporary.

The first furniture piece by

the team, the ‘linea 1200-S’; received the Award of Merit from the Design

Institute of Australia (WA) 2003 in Furniture Design, and was also

short-listed for International JEC Awards in the Design category for their

development in composites. |

|

|

McLaren composites, UK: First article

laminator for the

all composite

Mercedes SLR project. R&D technician for an

investigation into class A surface finishes to body panels. Component

manufacturing and testing for the Beagle Mars lander probe. |

|

|

DPS composites, UK - team member:

construction of 7 Jordan Formula

1 chassis and other related assemblies,

McLaren Formula 1

components, Le Mans and UK touring car assemblies and chassis.

|

|

|

Design Acumen, London UK -

modelmaker/patternmaker, full or small scale

construction of

first and business class interiors for

Airbus A380 clients to small private

business jets. |

|

|

Windrush Motorsport,

Australia - laminator: manufacture of various motorsport categories,

from Formula Ford and V8 Supercars to

World Rally teams,

requiring a variety of

construction processes and tooling solutions. |

|